ASC type anode carbon block stacker

Automated carbon block stacking equipment, suitable for aluminum electrolysis industry, accurately realizes the layered stacking of anode carbon blocks.

- Commodity name: ASC type anode carbon block stacker

Keyword:

ASC type anode carbon block stacker

ASC type anode carbon block stacker

- PRODUCT DESCRIPTION

-

Product Introduction

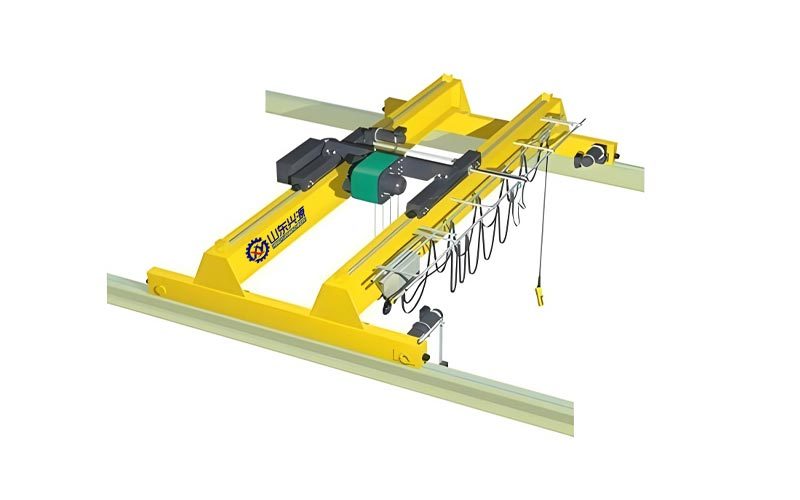

The suction and unloading trolley is a special equipment for roasting workshops in industries such as carbon, graphite, and negative electrode materials. It mainly consists of six major parts: bridge tray, large and small vehicle operating mechanism, suction and unloading system, cooling system, dust removal system, and electronic control system. Automatic stacking equipment specially designed for the electrolytic aluminum industry is equipped with fixtures and positioning systems to achieve efficient stacking of anode carbon blocks.

Main uses

The suction and unloading crane for roasting is a special crane serving the roasting of anode carbon blocks for aluminum electrolysis in the carbon industry. It integrates the functions of carbon block transfer and loading furnace, filling material suction and discharge, dust collection and transportation, and roasting equipment transfer operations, which can effectively improve the production efficiency of the anode roasting workshop and greatly improve the workshop operation environment.

Structural Advantages

Designed with pneumatic or mechanical self-gravity fixtures, it can clamp multiple carbon blocks at a time, with high clamping stability and anti-detachment performance, adapting to the explosive dust environment of aluminum electrolytic plants; the modular structure is compact, with a large span, and its weight is high, which is easy to install and maintain, and improves operating efficiency.

Parameter configuration

Product name Unit ASC Anode Carbon Block Stacker lifting capacity t 3—15 Span m 8—25 Ambient temperature ℃ —10~+50 lifting height m 3—12 Crane running speed m—mim 10-40 (with speed regulation function) lift mechanism and electric hoist operation mechanism Lifting mechanism lifting speed m—mim 3—10 Running mechanism operation speed m—mim 10—40 Lifting mechanism type Special clamping mechanism Work level A3-A6 Power 380V/50Hz Operational Agency Three-phase asynchronous motor (explosion-proof type)

FACTORY APPEARANCE

PACKING AND DELIVERY

CUSTOMER VISIT

HONOR

HONOR

The quality reaches the first-class level

It is a member unit of the China Crane Industry Association, a "national second-level enterprise", a first-level safety certification enterprise, an A-level installation, transformation, and maintenance enterprise, and a national designated manufacturer of lifting machinery. It has a mechanical engineering "Design Certificate", "Production License" and manufacturing, installation, repair, transformation, and maintenance "Safety Approval Certificate", and has passed ISO9001 quality system certification, ISO14001 environmental system certification and ISO45001 occupational health and safety management system certification.

FAQ

What’s the information should l provide when inquiry?

Can you provide custom service?

How do you guarantee the quality?

How do you package the product?

2.If the size are suitable for container ship, usually by container.

3.Big size, usually by bulk ship or by container after truncation

4.Transport ways are based on reducing cost & keep safety.

Are there professional technicians to assist in the installation?

What international certifications have your crane passed?

ONLINE INQUIRY