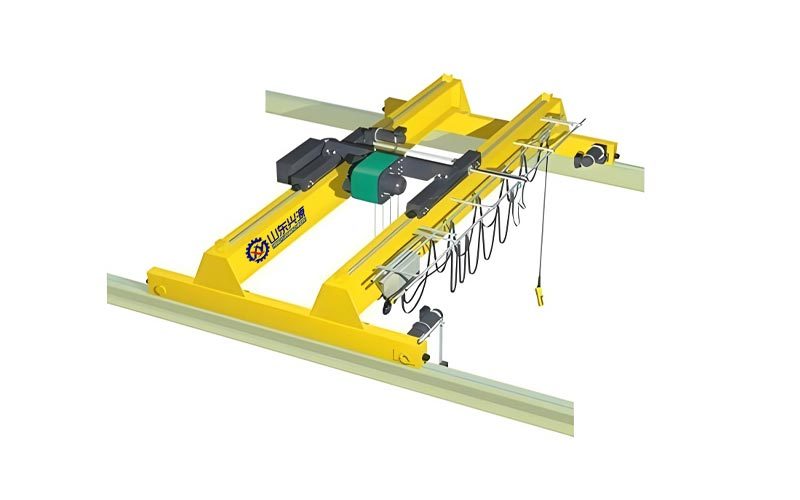

MHh electric hoist gantry crane (upper and lower fancy style)

The flower frame box-type door structure, lightweight design, and electric hoist, is suitable for light lifting needs in small and medium-sized factories and warehouses.

- Commodity name: MHh electric hoist gantry crane (upper and lower fancy style)

Keyword:

MHh electric hoist gantry crane (upper and lower fancy style)

MHh electric hoist gantry crane (upper and lower fancy style)

- PRODUCT DESCRIPTION

-

Product Introduction

MHn type electric hoist gantry crane (upper and down type) is a small and medium-sized crane that is used in rail-operated with CD1 and MD1 type electric hoists. Its main beams and legs adopt fancy upper and lower structures (such as box beams or truss type), which are lightweight and strong wind resistance. They are suitable for open-air and indoor operation scenarios and are widely used in material loading and unloading in factories, warehouses, docks and other places.

Main uses

It is suitable for general loading, unloading and handling operations in machining workshops, warehouses and other places, and is especially suitable for lifting heavy-duty materials such as large-scale boards and equipment, which can meet the needs of factory buildings of different sizes. It has good wind resistance and stability, and is often used for container loading and unloading and bulk cargo transfer at terminals and railway freight yards.

The upper part is a closed box-shaped cross-section, and the lower part adopts flower-frame trusses, taking into account both stiffness and lightweight, and is suitable for corrosive or high-wind speed environments. The plane rigid frame structure without inclined rods has clear stress and is suitable for complex civil engineering conditions.Structural Advantages

It uses a truss-type main beam structure that is welded in combination with I-steel and steel plate. It has a light weight and strong wind resistance, making it suitable for open-air or large-span working environments. The box-shaped double-beam welded structure enhances the overall stiffness, and at the same time, the main beam and the legs are connected by high-strength bolts, which is convenient for transportation and on-site assembly. The truss-type structure is designed to reduce on-site welding workload and shorten the installation cycle.

The door steel frame design avoids dependence on the top structure of the factory. Equipped with multiple protection devices to ensure safety during operation. Supports ground operation or cab operation to adapt to complex operating environments. Fancy top and bottom appearance design takes into account both practicality and aesthetics, suitable for the needs of modern industrial factory buildingsParameter configuration

Product name Unit MHn type electric hoist gantry crane (upper and down style) lifting capacity t 1—30 Span m 10-35 Ambient temperature ℃ —20~+40 lifting height m 6-30 meters Crane running speed m—mim 10-40 (multiple workstations) lift mechanism and electric hoist operation mechanism Lifting mechanism lifting speed m—mim 0.8—12 Running mechanism operation speed m—mim 8—30 Lifting mechanism type CD1—MD1 electric hoist Work level A3—A5 Power 380V/50Hz Operational Agency Conical rotor motor (optional with explosion-proof hoist)

FACTORY APPEARANCE

PACKING AND DELIVERY

CUSTOMER VISIT

HONOR

HONOR

The quality reaches the first-class level

It is a member unit of the China Crane Industry Association, a "national second-level enterprise", a first-level safety certification enterprise, an A-level installation, transformation, and maintenance enterprise, and a national designated manufacturer of lifting machinery. It has a mechanical engineering "Design Certificate", "Production License" and manufacturing, installation, repair, transformation, and maintenance "Safety Approval Certificate", and has passed ISO9001 quality system certification, ISO14001 environmental system certification and ISO45001 occupational health and safety management system certification.

FAQ

What’s the information should l provide when inquiry?

Can you provide custom service?

How do you guarantee the quality?

How do you package the product?

2.If the size are suitable for container ship, usually by container.

3.Big size, usually by bulk ship or by container after truncation

4.Transport ways are based on reducing cost & keep safety.

Are there professional technicians to assist in the installation?

What international certifications have your crane passed?

ONLINE INQUIRY