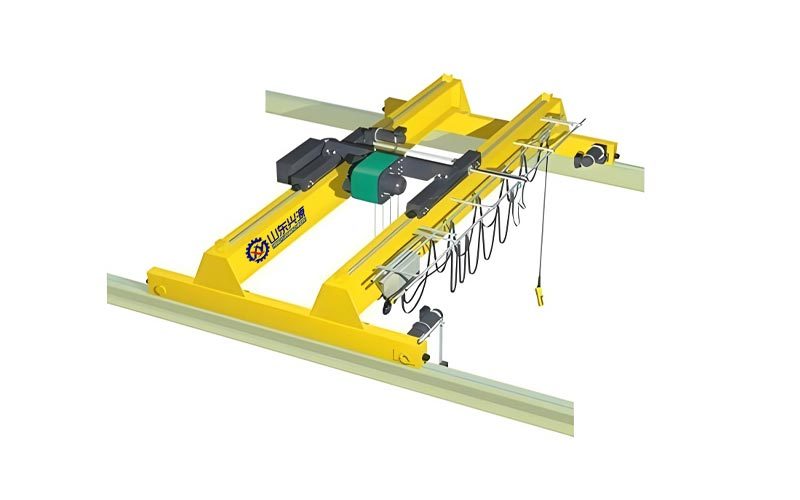

LDT electric single-beam bridge crane (height-in type)

Height-enhanced single-beam bridge cranes are suitable for factories or storage environments with special requirements for lifting height.

- Commodity name: LDT electric single-beam bridge crane (height-in type)

Keyword:

LDT electric single-beam bridge crane (height-in type)

LDT electric single-beam bridge crane (height-in type)

- PRODUCT DESCRIPTION

-

Product Introduction

It adopts box-shaped or U-shaped channel steel and I-shaped steel welded structures, which have both high strength, lightweight and stability, and is suitable for height-enhanced design needs. The main beam and the end beam are connected by high-strength bolts for easy transportation and installation. By optimizing the main beam height or increasing the lifting mechanism configuration, the needs of higher lifting heights are met. The supporting facilities are used with CD1, MD1, HC and other models of electric hoists.

Main uses

Suitable for high-rise shelf storage scenarios in warehouses or logistics centers, expanding vertical operating space through heightened design, improving cargo stacking and picking and placement efficiency. In workshops such as mechanical manufacturing and automobile assembly, it is used to hoist large parts or molds to higher workstations. For example, in automobile manufacturing, lifting the vehicle body to the high-rise station of the assembly line, or handling precision instruments in mold workshops, is used to lift light building materials to higher floors or construction platforms in construction sites, replacing some tower crane functions, and is especially suitable for small and medium-sized projects or scenes where site is restricted.

Structural Advantages

Compact and lightweight design, lightweight and small space occupies, suitable for factory buildings or warehousing environments with small and medium spans, reducing the load on the building structure and saving installation costs. The main beam usually uses box-type or I-shaped steel structures, with excellent bending and torsional resistance, stronger load-bearing capacity, and is not easy to deform for a long time, ensuring operational stability.

Increased lifting space to meet the needs of high-rise cargo lifting. Modular assembly is convenient, and the structural parts are designed in a modular manner, which is convenient for transportation, rapid installation and post-maintenance, reducing on-site construction time and maintenance downtime costs. The walking mechanism is stable and flexible.Parameter configuration

Product name Unit LDT type electric single-beam bridge crane (height-in type) lifting capacity t 1—32 Span m 7.5—35 Ambient temperature ℃ —20~+40 lifting height m 5—20 Crane running speed m—mim 20-80 (two-speed optional) lift mechanism and electric hoist operation mechanism Lifting mechanism lifting speed m—mim 0.8—8 Running mechanism operation speed m—mim 8—20 Lifting mechanism type CD1—MD1 electric hoist Work level A3-A5 Power 380V/50Hz Operational Agency Conical rotor motor (IP55 protection)

FACTORY APPEARANCE

PACKING AND DELIVERY

CUSTOMER VISIT

HONOR

HONOR

The quality reaches the first-class level

It is a member unit of the China Crane Industry Association, a "national second-level enterprise", a first-level safety certification enterprise, an A-level installation, transformation, and maintenance enterprise, and a national designated manufacturer of lifting machinery. It has a mechanical engineering "Design Certificate", "Production License" and manufacturing, installation, repair, transformation, and maintenance "Safety Approval Certificate", and has passed ISO9001 quality system certification, ISO14001 environmental system certification and ISO45001 occupational health and safety management system certification.

FAQ

What’s the information should l provide when inquiry?

Can you provide custom service?

How do you guarantee the quality?

How do you package the product?

2.If the size are suitable for container ship, usually by container.

3.Big size, usually by bulk ship or by container after truncation

4.Transport ways are based on reducing cost & keep safety.

Are there professional technicians to assist in the installation?

What international certifications have your crane passed?

ONLINE INQUIRY