Chain electric hoist

Lightweight electric hoists with chain hoists are suitable for lifting scenarios with limited space or frequent movement.

- Commodity name: Chain electric hoist

Keyword:

Chain electric hoist

Chain electric hoist

- PRODUCT DESCRIPTION

-

Product Introduction

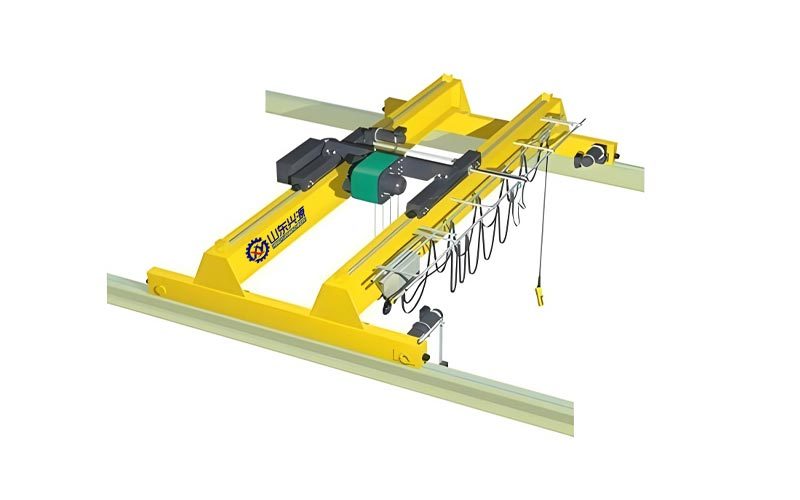

The electric chain hoist is a light and small lifting equipment. The chain electric hoist consists of an electric motor, a transmission mechanism and a sprocket. All chain electric hoists are produced in accordance with international standards. The body is beautiful, sturdy and durable. The internal gears are all quenched by high temperature, which increases the wear resistance and toughness of the gears. The body is made of high-strength stretched shell or die-cast aluminum shell, and is precisely manufactured by thin-wall extrusion molding technology, with small size, light weight and high strength. The standard chain electric hoist has an independent transmission system that seals the secondary coaxial transmission gear mechanism in the transmission and uses a long-life oil bath lubrication system. The electric hoist powder metallurgy clutch is used as an overload protection device. The brake uses a disc DC electromagnetic field to brake, with large braking torque, stable, rapid and low noise.

Main uses

It is very convenient for lifting heavy objects, loading and unloading work, maintenance equipment, and lifting goods. It can also be installed on suspended I-steel, curved tracks, cantilever lifting guides and fixed lifting points to lift heavy objects.

Structural Advantages

Compact and lightweight

The body uses a high-strength aluminum alloy shell or die-cast aluminum shell, which is lightweight and sturdy, and has excellent heat dissipation performance. It is suitable for places with limited space.

The transmission system is optimized, combined with alloy steel gears and oil bath lubrication system, which has a stable operation and long service life.

Multiple security protection

Equipped with reverse phase protection, upper and lower limit switches, overload protection and dual braking systems (electromagnetic braking + mechanical braking), to ensure rapid shutdown during overload or incorrect operation.

High-strength chains have high wear resistance and tensile strength, with a breaking tensile force of more than 4 times, making them more safe.

The components are highly versatile and support rapid disassembly and replacement, without complex commissioning during maintenance, reducing downtime.

Long life and low failure rate

The gear is strengthened by heat treatment, and the failure rate is lower than that of traditional wire rope hoists, and it is resistant to harsh environments.

Low noise operation: Disc brakes and optimized gear design reduce noise pollution.Parameter configuration

Product name Unit Chain electric hoist lifting capacity t 0.1—3 Span m — Ambient temperature ℃ —10~+40 lifting height m 3—10 Crane running speed m—mim 3-15 (precision low-speed control) Lifting mechanism and electric hoist operation mechanism Lifting mechanism lifting speed m—mim 0.5—6 Running mechanism operation speed m—mim 3—15 Lifting mechanism type Chain electric hoist Work level M3-M6 Power 380V/50Hz Operational Agency Three-phase asynchronous motor (low noise design)

FACTORY APPEARANCE

PACKING AND DELIVERY

CUSTOMER VISIT

HONOR

HONOR

The quality reaches the first-class level

It is a member unit of the China Crane Industry Association, a "national second-level enterprise", a first-level safety certification enterprise, an A-level installation, transformation, and maintenance enterprise, and a national designated manufacturer of lifting machinery. It has a mechanical engineering "Design Certificate", "Production License" and manufacturing, installation, repair, transformation, and maintenance "Safety Approval Certificate", and has passed ISO9001 quality system certification, ISO14001 environmental system certification and ISO45001 occupational health and safety management system certification.

FAQ

What’s the information should l provide when inquiry?

Can you provide custom service?

How do you guarantee the quality?

How do you package the product?

2.If the size are suitable for container ship, usually by container.

3.Big size, usually by bulk ship or by container after truncation

4.Transport ways are based on reducing cost & keep safety.

Are there professional technicians to assist in the installation?

What international certifications have your crane passed?

ONLINE INQUIRY