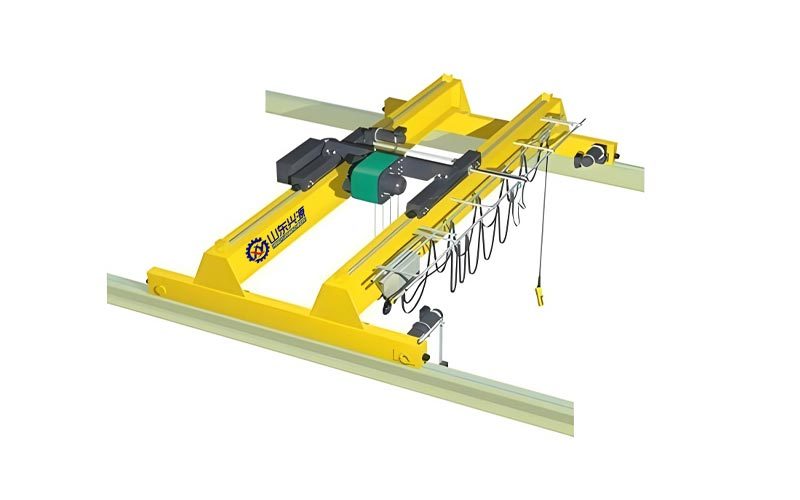

MGE gantry crane (double trolley)

Gantry crane equipped with double trolleys supports multi-task collaborative lifting and meets the industrial needs of large spans and high loads.

- Commodity name: MGE gantry crane (double trolley)

Keyword:

MGE gantry crane (double trolley)

MGE gantry crane (double trolley)

- PRODUCT DESCRIPTION

-

Product Introduction

MGE double-car universal gantry crane is a heavy lifting equipment suitable for open-air warehouses, port terminals, railway freight stations and other scenarios, mainly used for loading, unloading, handling and special operations. Its dual trolley design can complete multi-task operations such as lifting and transportation at the same time, significantly improving operational efficiency

Main uses

The port terminal container loading and unloading, the double-trolley design can complete the container lifting and stacking operations at the same time, improving loading and unloading efficiency. Adapt to containers of different specifications.

The coordinated operation of the double-car can realize the "main hook hoisting + secondary hook assist" mode, such as flipping large goods or handling special materials with special hooks.

The dual-trolley configuration of shipbuilding and large-scale engineering supports complex lifting needs, such as lifting and flipping of hulls in segments, or lifting of large-piece components in bridge construction.Structural Advantages

Coordinated operation of double trolleys: Through the cooperation of two lifting trolleys, the lifting, turning over and precise positioning of heavy objects can be achieved, especially suitable for lifting large components, improving operational efficiency and safety.

Box-type double beam welded structure: The bridge adopts a high-strength box-type double beam design, which significantly enhances the overall stiffness and bending resistance, and adapts to the needs of large tonnage and complex working conditions.

Drive and variable frequency speed regulation: The vehicle operating mechanism adopts separate drive to avoid operating skews; the vehicle is equipped with a variable frequency speed regulation system to achieve stable lifting and walking, and meet the requirements of micro-movement operation.

Flexible legs design: One side adopts flexible legs to compensate for temperature deformation of the bridge frame and reduce lateral thrust, suitable for large span scenarios.

Modularity and convenient maintenance: bridge trays, legs and other components are bolted for easy disassembly, assembly and transportation.Parameter configuration

Product name Unit MGE Gantry Crane (Twin Tile) lifting capacity t 20—200 Span m 7—60 Ambient temperature ℃ —20~+40 lifting height m 15—60 Crane running speed m—mim 20-38 (two-car collaboration) lift mechanism and electric hoist operation mechanism Lifting mechanism lifting speed m—mim 1.6—16 Running mechanism operation speed m—mim 20—90 Lifting mechanism type Double Winding Lifting System Work level A5-A8 Power 380V/50Hz Operational Agency Dual frequency conversion three-phase asynchronous motor

FACTORY APPEARANCE

PACKING AND DELIVERY

CUSTOMER VISIT

HONOR

HONOR

The quality reaches the first-class level

It is a member unit of the China Crane Industry Association, a "national second-level enterprise", a first-level safety certification enterprise, an A-level installation, transformation, and maintenance enterprise, and a national designated manufacturer of lifting machinery. It has a mechanical engineering "Design Certificate", "Production License" and manufacturing, installation, repair, transformation, and maintenance "Safety Approval Certificate", and has passed ISO9001 quality system certification, ISO14001 environmental system certification and ISO45001 occupational health and safety management system certification.

FAQ

What’s the information should l provide when inquiry?

Can you provide custom service?

How do you guarantee the quality?

How do you package the product?

2.If the size are suitable for container ship, usually by container.

3.Big size, usually by bulk ship or by container after truncation

4.Transport ways are based on reducing cost & keep safety.

Are there professional technicians to assist in the installation?

What international certifications have your crane passed?

ONLINE INQUIRY