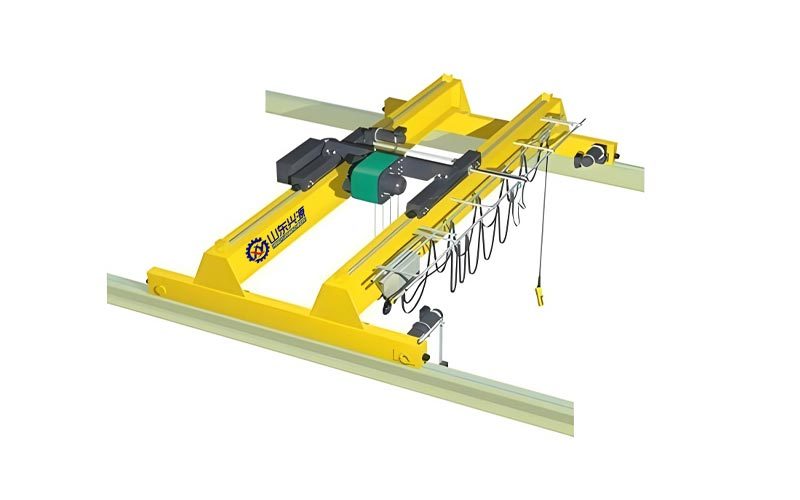

MGN type gantry crane

General-purpose gantry crane is suitable for material loading and unloading and large-span hoisting operations in open-air cargo yards, storage yards and other scenes.

- Commodity name: MGN type gantry crane

Keyword:

MGN type gantry crane

MGN type gantry crane

- PRODUCT DESCRIPTION

-

Product Introduction

The main structure adopts a double-main beam box-type welded bridge, and the legs are variable-section box-shaped structures to enhance bending and torsional resistance.

The operating mechanism of the large truck is driven separately. The small truck is equipped with an electric hoist or lifting mechanism, and the operating room is centrally controlled. Supports power supply of cable reels or sliding wires, and PLC control improves automation levelMain uses

It is suitable for large logistics nodes such as port terminals, railway freight stations, and open-air material yards. It is used to load and unload parts of cargo and bulk materials, especially suitable for cross-track operations and can cover large-area yards. The double main beam structure provides high load-bearing capacity, and the large span design meets different site needs.

Heavy equipment components can be transported in machinery manufacturing workshops, metallurgy plants, assembly lines, etc., and special materials can be handled with electromagnetic suction cups or grabs. Support frequency conversion control, realize accurate positioning and speed adjustment, and adapt to high-frequency and high-intensity operations. Bridge construction, power plant equipment installation, ship manufacturing, etc. The lifting of large prefabricated components can be expanded with the cantilever design to meet complex installation needs.

Single/double hooks, different lifting speeds, sliding contact wires or cable power supply can be configured according to requirements to adapt to high temperature and high humidity environments.Structural Advantages

The box-shaped double main beam welded with high-strength steel plate has excellent cross-sectional bending stiffness and torsional resistance. The main beam and the legs are bolted by flange, which is easy to transport and modularly assemble on site, reducing the need for large-scale welding operations. Stiffening ribs are installed inside the main beam to optimize stress distribution, reduce self-weight and improve deformation resistance. The span coverage is large and can adapt to different site needs. The matching design of rigid legs and flexible legs effectively compensates track installation errors and temperature deformation, and reduces the phenomenon of "getting the rail". The wire rope guide device is equipped with a multi-layered winding anti-chaos rope design to reduce the risk of breaking rope.

Parameter configuration

Product name Unit MGN type gantry crane lifting capacity t 5—100 Span m 7—50 Ambient temperature ℃ —20~+40 lifting height m 10—50 Crane running speed m—mim 30-100 (large span) lift mechanism and electric hoist operation mechanism Lifting mechanism lifting speed m—mim 1.6—16 Running mechanism operation speed m—mim 30—100 Lifting mechanism type Hyundated Winding System Work level A5-A7 Power 380V/50Hz Operational Agency Three-phase asynchronous motor (frequency conversion + braking) Product name Unit MGN European gantry crane lifting capacity t 10—100 Span m 20—50 Ambient temperature ℃ —20~+40 lifting height m 10—40 Crane running speed m—mim 25-90 (Large span optimization) Lifting mechanism and electric hoist operation mechanism Lifting mechanism lifting speed m—mim 1.6—16 Running mechanism operation speed m—mim 25—90 Lifting mechanism type European winching system Work level A5 Power 380V/50Hz Operational Agency Frequency variable frequency three-phase asynchronous motor (dust and waterproof design)

FACTORY APPEARANCE

PACKING AND DELIVERY

CUSTOMER VISIT

HONOR

HONOR

The quality reaches the first-class level

It is a member unit of the China Crane Industry Association, a "national second-level enterprise", a first-level safety certification enterprise, an A-level installation, transformation, and maintenance enterprise, and a national designated manufacturer of lifting machinery. It has a mechanical engineering "Design Certificate", "Production License" and manufacturing, installation, repair, transformation, and maintenance "Safety Approval Certificate", and has passed ISO9001 quality system certification, ISO14001 environmental system certification and ISO45001 occupational health and safety management system certification.

FAQ

What’s the information should l provide when inquiry?

Can you provide custom service?

How do you guarantee the quality?

How do you package the product?

2.If the size are suitable for container ship, usually by container.

3.Big size, usually by bulk ship or by container after truncation

4.Transport ways are based on reducing cost & keep safety.

Are there professional technicians to assist in the installation?

What international certifications have your crane passed?

ONLINE INQUIRY