Multi-functional sky truck for suction and discharge

Used for material suction and handling in metallurgy, chemical industry and other industries, with efficient and multifunctional operation capabilities.

- Commodity name: Multi-functional sky truck for suction and discharge

Keyword:

Multi-functional sky truck for suction and discharge

Multi-functional sky truck for suction and discharge

- PRODUCT DESCRIPTION

-

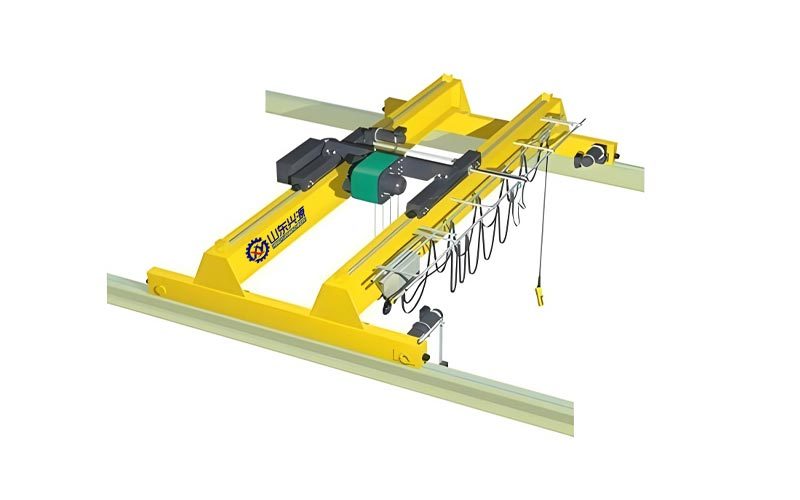

Product Introduction

The filler is accurately filled into the furnace pit through the discharge pipe, or the high-temperature filler is sucked out by the suction pipe and the ash is separated.

Auxiliary hoisting: An electric hoist is equipped under the bridge tray, which can complete auxiliary hoisting tasks such as charcoal blocks and equipment.

Environmental purification: Integrated dust removal system to reduce dust pollution during operation and improve the working environment.Main uses

1. Use the discharge pipe to fill the filler into the furnace pit;

2. Use suction pipe to suck high-temperature filler out of the furnace pit and separate the ash;

3. There is an electric hoist under the bridge to assist in lifting. The entire vehicle adopts P LC control and frequency conversion speed regulation configuration.

It has now been widely used in major carbon factories across the country, reaching the international advanced level, greatly improving the harsh working environment, reducing the labor intensity of workers and improving work efficiency.Structural Advantages

The multi-functional cyclist with high-efficiency operation and intelligent management has the advantages of accurate operation and can operate stably in high-temperature and dusty environments. Its modular design supports the integration of multi-functional materials absorption, unloading and lifting, and is equipped with electric hoists to assist in handling, which significantly improves the material processing efficiency of the pre-baked anode workshop in the carbon industry. Through automated transportation, reduce manual intervention, reduce labor intensity and safety hazards, and is equipped with fault alarm and real-time monitoring functions to ensure the reliability of equipment operation.

Parameter configuration

Product name Unit Multi-functional sky truck lifting capacity t 5—30 Span m 12—35 Ambient temperature ℃ —20~+40 lifting height m 5—20 Crane running speed m—mim 20-60 (adjust to the working condition) lift mechanism and electric hoist operation mechanism Lifting mechanism lifting speed m—mim 5—15 Running mechanism operation speed m—mim 20—60 Lifting mechanism type Special lifting mechanism Work level A5-A8 Power 380V/50Hz Operational Agency Conical rotor motor/three-phase asynchronous motor

FACTORY APPEARANCE

PACKING AND DELIVERY

CUSTOMER VISIT

HONOR

HONOR

The quality reaches the first-class level

It is a member unit of the China Crane Industry Association, a "national second-level enterprise", a first-level safety certification enterprise, an A-level installation, transformation, and maintenance enterprise, and a national designated manufacturer of lifting machinery. It has a mechanical engineering "Design Certificate", "Production License" and manufacturing, installation, repair, transformation, and maintenance "Safety Approval Certificate", and has passed ISO9001 quality system certification, ISO14001 environmental system certification and ISO45001 occupational health and safety management system certification.

FAQ

What’s the information should l provide when inquiry?

Can you provide custom service?

How do you guarantee the quality?

How do you package the product?

2.If the size are suitable for container ship, usually by container.

3.Big size, usually by bulk ship or by container after truncation

4.Transport ways are based on reducing cost & keep safety.

Are there professional technicians to assist in the installation?

What international certifications have your crane passed?

ONLINE INQUIRY