ABOUT XINGYUAN

Company Profile

Shandong Xingyuan Machinery Co., Ltd. is a professional factory that produces various types of cranes. Shandong Xingyuan Machinery Co., Ltd. was established in 2004 and became an independent legal entity with a registered capital of 121.7 million yuan in 2007. It is mainly engaged in the design, manufacture, installation, repair, transformation, maintenance of hook bridge gantry cranes, grab bridge gantry cranes, variable frequency cranes, explosion-proof series cranes, electric hoists, chain-type oil scrapers, foam scrapers, and elevator installation and maintenance.

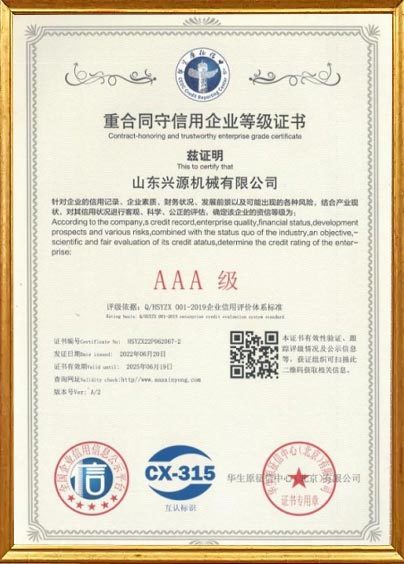

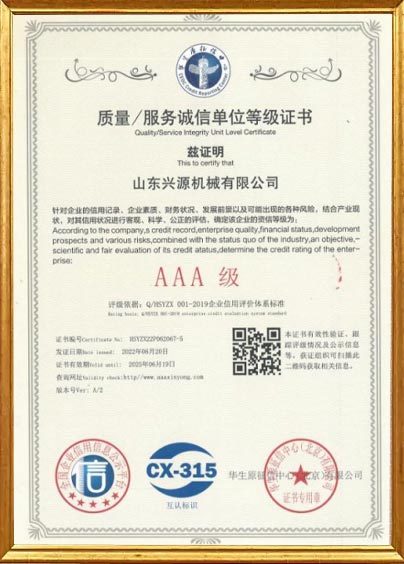

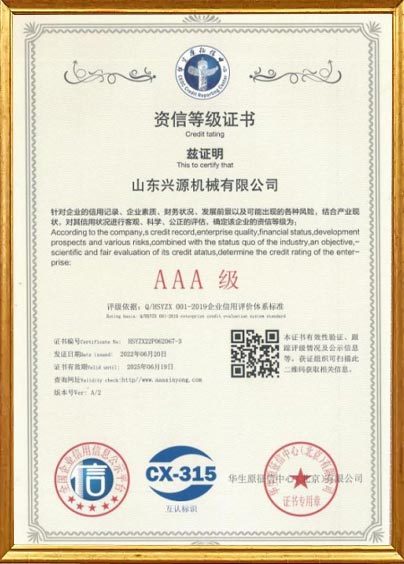

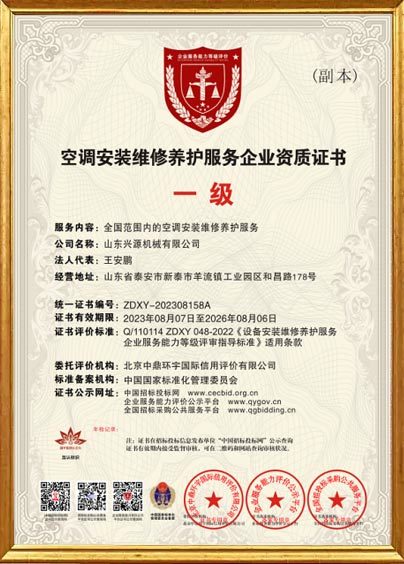

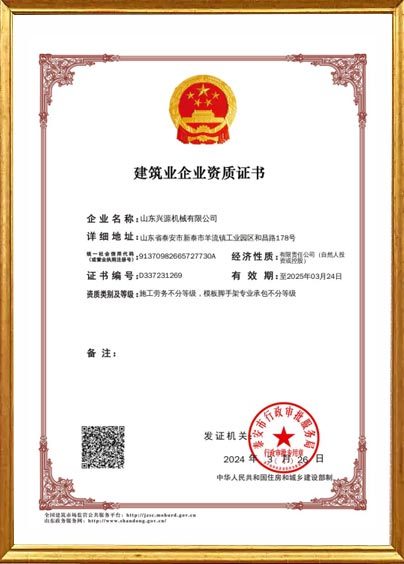

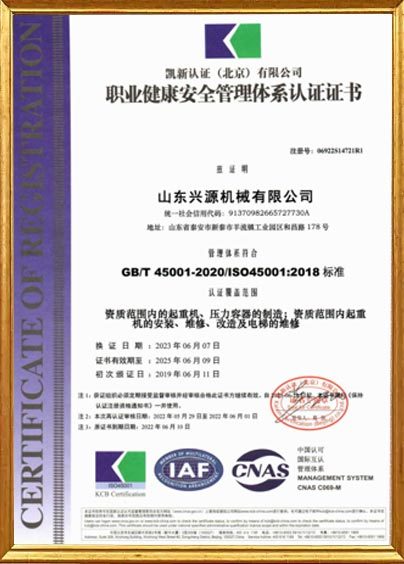

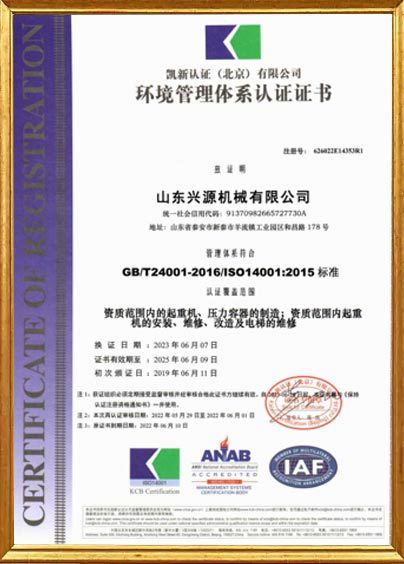

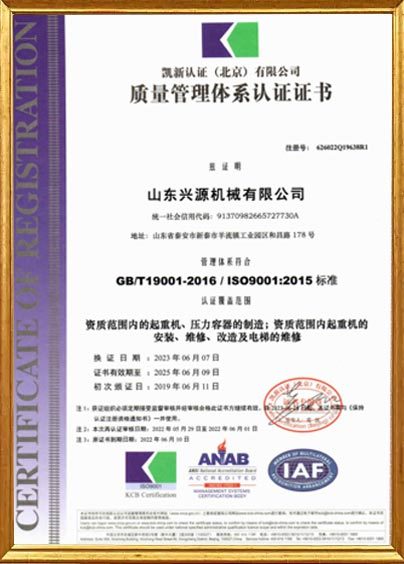

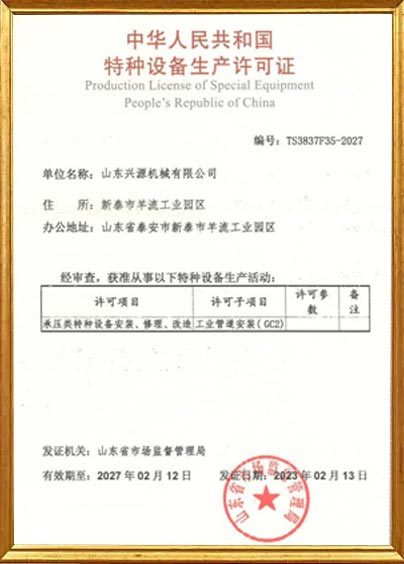

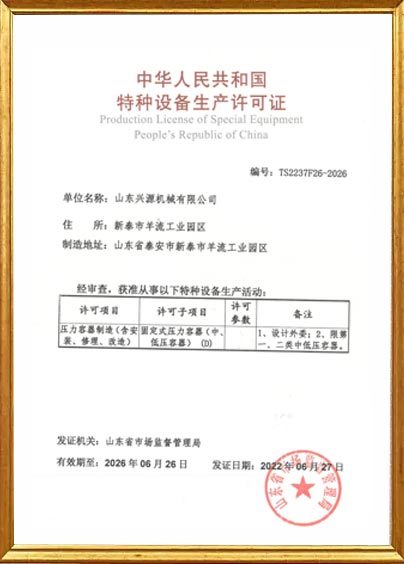

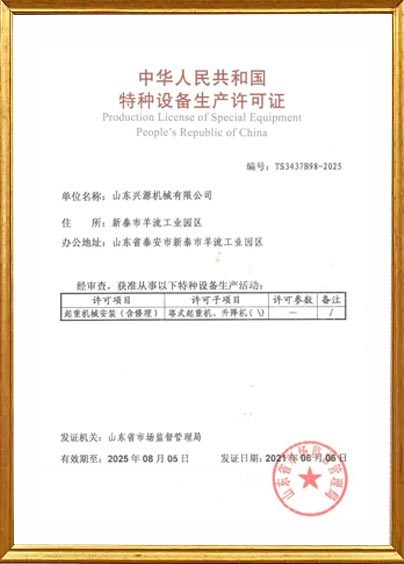

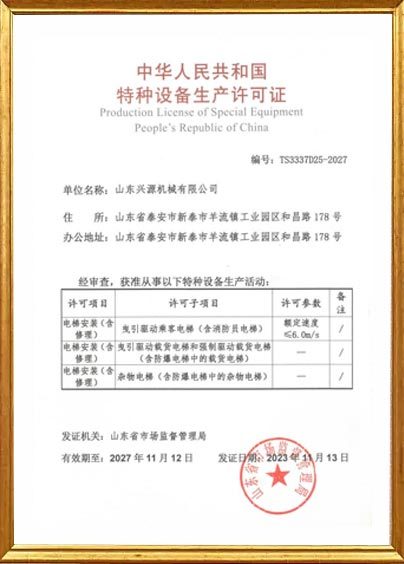

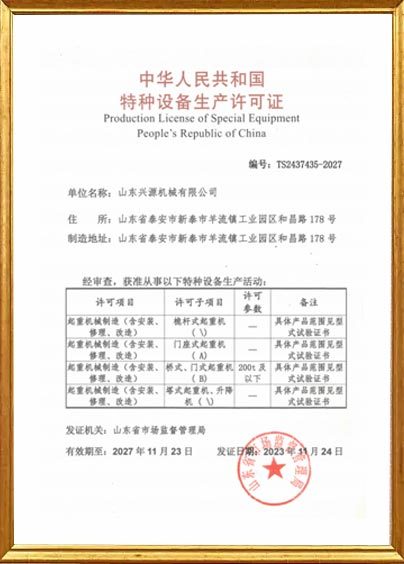

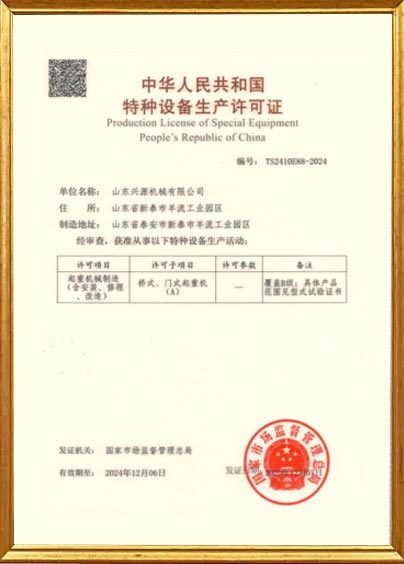

It is a member unit of the China Crane Industry Association, a "national second-level enterprise", a first-level safety-recognized enterprise, an A-level installation, modification and maintenance enterprise, a national designated manufacturer of lifting machinery, with mechanical engineering "Design Certificate", "Production License" and manufacturing, installation, repair, modification and maintenance "Safety Approval Certificate", and has passed ISO9001 quality system certification, ISO14001 environmental system certification and ISO45001 occupational health and safety management system certification.

The company now covers an area of 42,000 square meters, including 10,000 square meters of production workshops and 2,000 square meters of outdoor large-scale door crane operation sites. It has fixed assets of more than 85.6 million yuan, an annual output value of several hundred million yuan, and profits and taxes of tens of millions of yuan. There are 286 employees, including 46 professional and technical personnel, and a team that can independently carry out product development and design; the company also has more than 160 sets of major key equipment and testing instruments such as professional riveting and welding, mechanical processing, shot blasting and rust removal, Kaiping and leveling, and has a large CNC blanking line, automatic submerged arc welding production line, CO2 gas shielded welding and other production lines, which strongly guarantee the company's product quality.

The company has advanced production and manufacturing capabilities, with 320 sets of main production equipment, including 11 large-scale precision equipment, which can independently complete all process flows such as turning, milling, planing, grinding, rolling, boring, drilling, cutting, bending, stamping, rolling, riveting, testing and heat treatment. At present, except for electrical components, other products are manufactured in the factory and the quality reaches the first-class level.

HONORS AND QUALIFICATIONS

OUR ADVANTAGES

We provide tracking services for the entire process of products required by customers, from design and manufacturing, factory inspection, transportation and installation, repair and maintenance.

Enterprise spirit

Standardization,value,serialization,differentiation, always beyond our contract.

Corporate vision

We are committed to becoming a global enterprise trusted and loved by the public.

Core values

Honest and trustworthy, performance oriented, people-oriented innovation and development.

Business philosophy

Pioneering, innovation, based on market demand development, heart service for clients.

FACTORY FACILITIES

The tolerance of the flattening machine meets the needs of sheet metal processing

Boring and drilling machines are multifunctional and can precisely process complex parts.

Neatly planned and well-organized spare parts warehouse to ensure timely delivery

Rapid, strong and compact welding to produce reliable products

Random sampling and careful material testing to ensure product quality

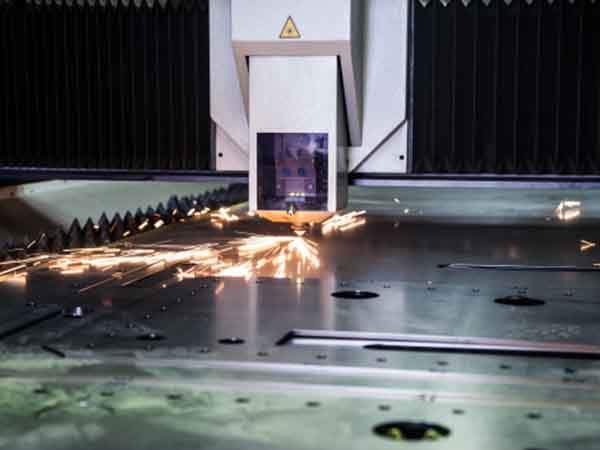

High-precision laser cutting machines for precision assembly processes

DEVELOPMENT HISTORY

The company now covers an area of 42,000 square meters, including 10,000 square meters of production workshops and 2,000 square meters of outdoor large-scale door crane operation sites. It has fixed assets of more than 85.6 million yuan, an annual output value of several hundred million yuan, and profits and taxes of tens of millions of yuan.

FAQ

What’s the information should l provide when inquiry?

Can you provide custom service?

How do you guarantee the quality?

How do you package the product?

2.If the size are suitable for container ship, usually by container.

3.Big size, usually by bulk ship or by container after truncation

4.Transport ways are based on reducing cost & keep safety.

Are there professional technicians to assist in the installation?

What international certifications have your crane passed?